46

|

Variable air volume controllers

Room pressure ratio

In a master / slave connection, any changes in the air

system of the master (supply pressure too low, e.g. due to

a pressure control fault) are detected and reported to the

slave. This guarantees an equal percentage ratio of supply

air to exhaust air.

In a master / slave configuration, only one controller can

act as master. However, one master controller can control

several parallel slave controllers.

When are master / slave connections used?

y

y

In systems with air volume controllers in the supply

and exhaust air that are required to work sequentially

y

y

When an equal percentage ratio of supply air to ex-

haust air is specified.

Operating volumetric flow settings

The max- and min values used for the required volu-

metric flow are set on the master and transferred to the

slave by means of a reference signal.

CAV application

In constant air volume applications, operating mode con-

trol (CLOSED /

min etc.) is only set on the master controller.

Slave setting if the room pressure ratio is balanced

The min setting on the slave is always 0%. If the room

pressure ratio is 1:1 and all controllers are the same size,

the slave controller is set to max 100% / min 0%.

Slave setting if the room pressure ratio is unbalanced

The min setting on the slave is always 0%.

Setting with % scale on the ZTH-GEN hand-operated

device

The ratio of slave volume to master volume is set as fol-

lows with the max value on the slave controller:

max S% =

max S •

nom M

•100

max M •

nom S

max S% = max value that must be set on the controller in %

nom M = Nominal volume of the master unit in m 3 /h

max M = Maximum volume of the master unit in m 3 /h

nom S = Nominal volume of the slave unit in m 3 /h

max S = Maximum volume of the slave unit in m 3 /h

Example

Required:

Positive pressure in the room with 20% excess air

– Supply air unit:

nom 1600 m 3 /h / max 1500 m 3 /h

– Exhaust air unit:

nom 2400 m 3 /h / max 1200 m 3 /h

Find: max setting of the slave controller

Setting with PC-Tool / ZTH-GEN

These two setting tools can be used to enter the volumetric flow ratio

directly in m 3 / h, ll/s or cfm, i.e. there is no need to calculate the setting

ratio.

53% =

1200 • 1600

•100

1500 • 2400

Determination of the master controller

If both units have:

y

y

Non-identical

nom

settings, the controller with the

lower

nom

.

y

y

Identical

nom

settings, the controller with the higher

air olume setting acts as master

y

y

Positive pressure in the room

Master: Supply air unit

Slave: Exhaust air unit

y

y

Negative pressure in the room

Master: Exhaust air unit Slave: Supply air unit

Principle:

1. A reference signal, e.g. from a room temperature con-

troller, is connected to the master input.

min

and

max

are set on the master controller.

2. The volumetric flow actual value signal from the

master acts as a reference signal for the slave control-

ler. The master is installed on the supply or exhaust air

side, depending on the application. See “Determination

of the master controller“.

For connection diagram, see page 39-42

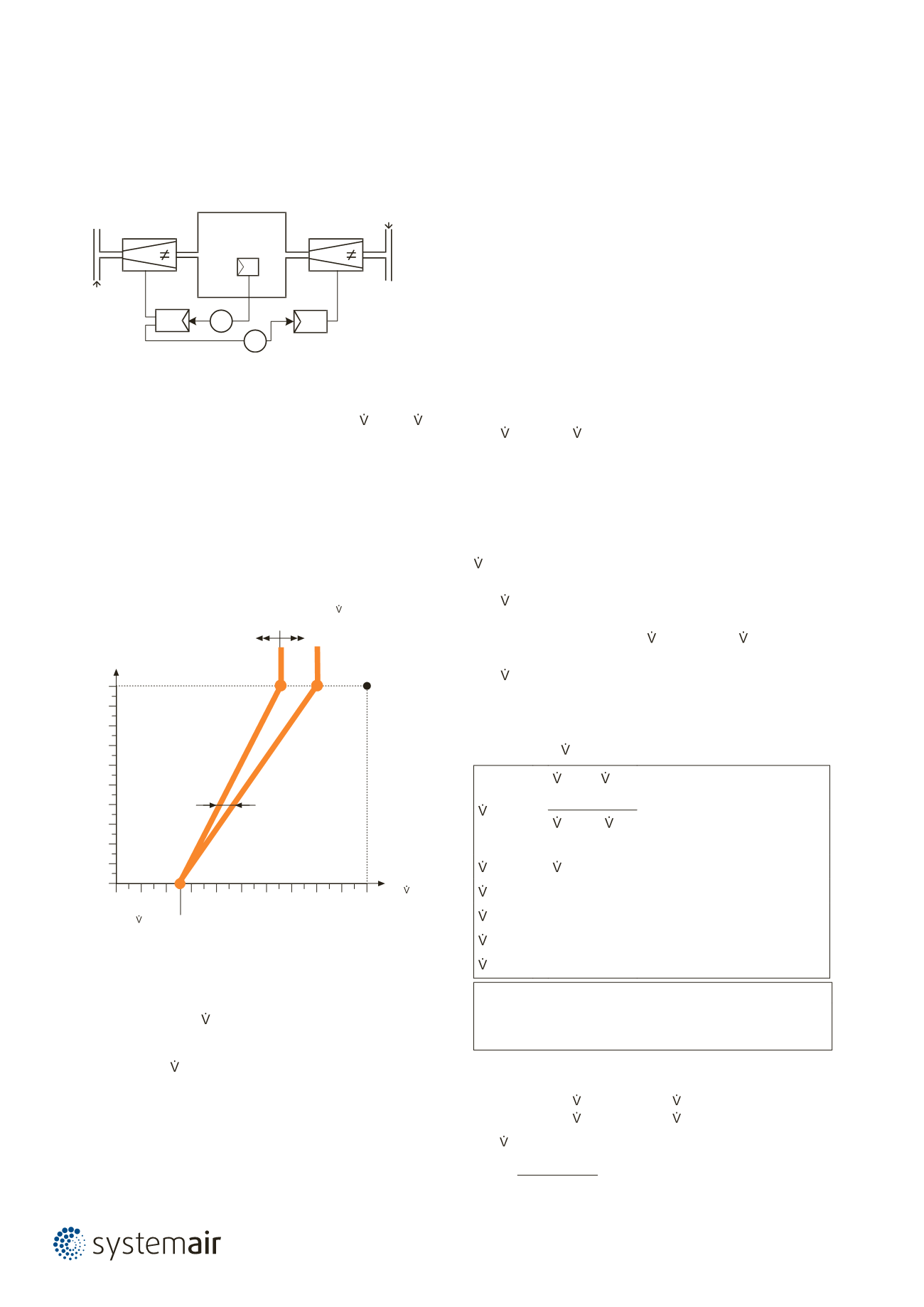

0

100

20

40

60

80

[V]

nom

10

0

2

4

6

8

max

max

min

Reference signal Y

Example with

mode: 0 … 10 V

The ratio is set with the max

parameter on the slave

Volumetric flow

[% nom ]

The slave min setting «0%» forms the pivot and intersection point

Equal percentage

ratio

Slave

Master

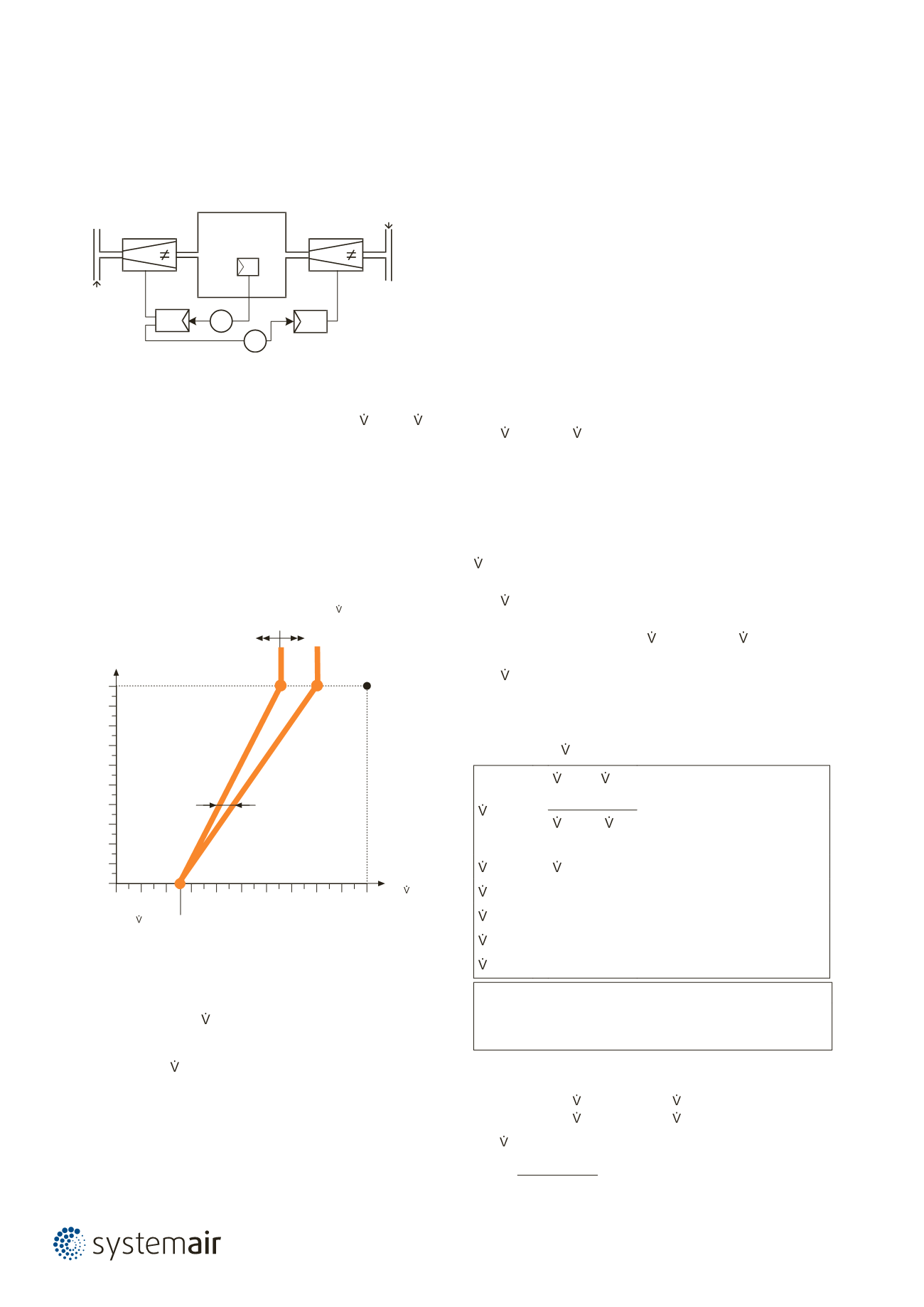

VAV-Compact

Functions

T

M

S

1

2

SUPPLY

EXHAUST

Room

Master / slave connection